MS Python’s Continuous Tank Monitoring and Leak Detection System is safer and more cost-effective for storage tanks than traditional methods. Unlike traditional methods, where a complete stop is often required for inspection, MS Python’s monitoring is conducted during normal usage providing real-time feedback on system health.

Learn More Get in TouchMS Python is the most advanced and reliable storage tank monitoring system of its kind. Even with pre-existing corrosion protection and leak detection in place, all single-walled underground storage tank systems will eventually leak as they age.

MS Python’s remote monitoring system is designed to monitor temperature change and detect leaks before problems occur. This provides operators with time to plan for regular maintenance, achieve efficient shutdown patterns, and avoid major system failures. With MS Python in place businesses can benefit from reductions in repair time, thus maximizing profits through increased plant availability.

Our customers receive reliable data to help them improve their operations, plan for ongoing maintenance, and identify obsolete structures for replacement.

A successful monitoring solution must consider the specific elements of the structure, requiring sophisticated planning, design and execution.

We have the knowledge and experience to establish baseline structural health reports, maintain long-term monitoring to track equipment degradation, and perform rapid condition screening to quickly identify the structure’s health following extreme events.

Storage tank systems without double walls or secondary containment pose a higher risk to the environment because, in the event of a leak or spill, product is released directly into soil and water. Once there, it can migrate over a considerable distance and cause extensive and long-term damage to the environment. If the system you operate or own has tanks, piping or sumps as described in the list below, then MS Python’s monitoring services should be part of your installation.

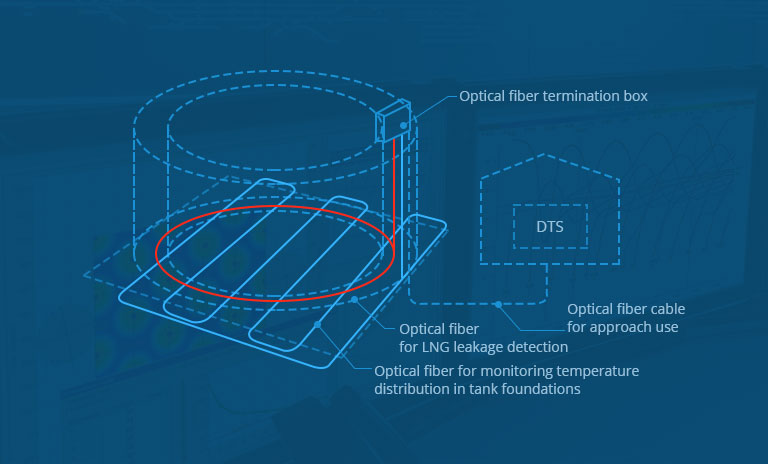

To provide comprehensive monitoring services for our customers, MS Python combines two different kind of technology: Distributed Temperature Sensors (DTS) and Acoustic Emission (AE) sensing. Please give us a call today so we can discuss the most effective solution for your business needs.

By providing two different kinds of technologies, MS Python allows us to offer our customers with comprehensive solutions to achieve the objectives of their project. We will work with you to determine the best implementation for your needs.

Implementing fiber optics sensing technology provides an ultra-stable, continuous sensor over long distances to detect the following:

These systems are highly accurate, providing location information in real time following an event. Further, our systems are intelligently designed to filter background noise from specific acoustic noise, so that alarms are only triggered by relevant events.

Through recent developments in technology, our services can provide fiber optic system monitoring along 60 km of pipeline using a single fiber, and extended applications of up to 300 km with the use of optical amplifiers.

With the ability to measure temperature and strain over thousands of points along a single fiber, our customers can utilize this essential technology for a wide range of monitoring needs, such as: verifying normal pipeline operation, detecting pipeline leakages, and preventing pipeline failure in landslide prone areas.

Detection services can further be used for optimizing oil well production and detecting hot spots in high-power cables, among other implementations.

Buried pipeline leakages pose several problems for owners. Financially, valuable product is wasted. Environmentally, product leaks into surrounding soil and contaminates the ground and water systems. And from a Health and Safety perspective, flammable products can cause fires, explosions, and respiratory issues.

With MS Python’s monitoring services, AE sensing monitors elastic or stress waves that are generated when an event occurs within or along a material’s surface, and send feedback alerts to key personnel to take action in real-time.

AE literally allows you to "listen" to the sounds of cracks growing, fibers breaking and many other modes of active damage in stressed materials.

This technology offers our customers a low-cost solution to monitor hundreds of kilometers of pipeline infrastructure, all with high measurability and spatial resolution. Common implementations include:

Leaking buried pipelines pose a very serious problem to pipeline owners for many reasons. Financially, due to the waste of valuable product, environmentally because the product may leak into surrounding soil and contaminate the ground, and safetywise, particularly if the leak is inside industrial facilities, when the product is flammable. Shutting down a pipeline that is suspected to leak may also lead to serious operational and financial implications (shortages, inability to deliver, contractual issues etc.). Occasionally, there are indications of a leak, e.g. when pressure is dropping for no other obvious reason or when product is visible in nearby valve wells, pipe ground exit points, seawater, on the ground itself etc. Even then, it is generally difficult to reliably locate the exact position of the leak so as to take corrective measures. In the worst case, a leak may go on unnoticed, such as in some cases of complex networks, or when it is not large enough to become visible.

Access to the pipeline is required only every about 100-200m for mounting AE sensors. Pipeline is pressurized in 500-1000m sections at a time, while the AE sensors detect the turbulent flow at the leak orifice, and, with the use of digital AE systems and specialized data acquisition and analysis software, provide the position of the leak. The method has been proven effective, fast and accurate in detecting and locating leaks, and it is now being used also as a preventive leak control tool for long underground transfer pipes or short, buried pipe sections, such as dikes and road crossings. Acoustic emission sensors operating between 20 and 100 kHz are mounted on the pipeline, monitoring both continuous and burst type emissions through simultaneous acquisition of Time Driven Data (threshold independent sampling) and Hit Driven Data (threshold dependant). In addition to that, acquisition of AE waveforms or waveform streaming is often used as a further evaluation tool.

Leaking valves are a common problem with results showing that 5 to 10 percent of the valves in Oil and Gas plants leak. More importantly, it was determined that just 1 to 2 percent of the valves accounted for approximately 70 percent of the losses. Valve leak detection works by detecting the “noise” produced as the medium passes through the valve as “turbulent” flow. Turbulent flow creates a signal with frequency components well over 100 KHz. This allows the use of high frequency acoustic emission sensors with frequencies above the vibration and background noise level of the plant. This characteristic makes reliable detection and quantification of leaks possible. In addition to being able to determine if a valve is leaking, our proprietary algorithms allow us to “quantify” the amount of the leak.

Successful detectability of leaks with AE depends upon the distance of the leak from the AE sensors, the attenuation characteristics of the pipe material (thickness, material etc.) and the type of fluid (gas, liquid) inside the pipe. It also depends upon the surrounding environment (air, soil) and the condition (Reynolds number) at the leak orifice, which, in turn, depends on flow rate, differential pressure, orifice size, and type of fluid.

Pipeline Integrity Monitoring System (PIMS) provides real-time integrity monitoring and is based on Brillouin or Raman scattering, FBG and/or Acoustic Emission (AE) sensing depending on the project requirements. MS Python Monitoring System detects and locates small temperature and or strain changes along the entire length of a pipeline continuously, in real time.

Get instantaneous feedback on your critical infrastructure from MS Python’s Pipeline Monitoring Services.

Innovative technology provides advanced analytics for leak detection, foreign intrusion, deformation, erosion, ground movement, geologic hazard detection, and pig position tracking.

Actively monitor your infrastructure to detect damage before it reaches a critical state.

Avoid system shutdowns due to time-consuming troubleshooting methods.

Implement advanced monitoring services that are directly integrated with your existing SCADA compatible system.

MS Python offers storage tank system health monitoring, providing customers with advanced technology to assess temperature change, corrosion and deposits, crack and leak detection in real-time. With MS Python in place, you will have all the information you need to identify the precise location of the problem and make an informed decision to repair it.

MS Python’s monitoring services deliver complete solutions seamlessly combining FBG technology and innovative, high-speed laser beam sensors into an integrated system. Through this approach, the system can be easily scaled to any size and configuration, with all data synced through a central monitoring center.

Monitor performance degradation and receive warning notifications to perform preventative maintenance and ensure the safety of personnel following significant events.

Our solution provides complete remote control over the operation reliability of boilers with simultaneous monitoring of such parameters as temperature change, the thickness layer of the pipes of all sizes and configurations. It also helps better schedule maintenance works and reduce operational costs.

Get an immediate status update about the system’s health, including possible damage and failures, following adverse events.

At MS Systems we provide innovative solutions that serve our customers needs through ultra-reliable performance and long product life. We believe in providing clear information about each service we offer, and the standards we aim to achieve.

Our team of experts will work closely with you during design, technology selection, and system optimization.

MS Systems provides service and support during and after installation, with a wide range of additional services and extended global warranties for every system we supply.

MS Systems provides ongoing technical support from installation, commissioning and beyond.

MS Systems provides a unique approach to structural health monitoring, delivering real-time data and analysis for our customers to reduce downtime by monitoring assets and notifying key members before it reaches a critical state.