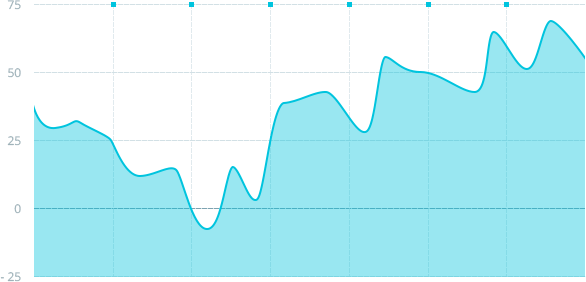

Uptime and safety are critical factors for conveyor belt operators. A key focus of our system is monitoring temperature change as coal is transported along the conveyor. Given coal’s highly explosive nature, monitoring temperature increases and alerting operators, provides advanced warning so they can take action and avoid critical events. Let MS Scorpion’s Structural Health Monitoring (SHM) help you implement a monitoring system, to actively assess the health and safety of your conveyor belt system.

Learn More Get in TouchMS Scorpion’s SHM system provides rapid assessment of our customer’s conveyor belt system to determine their current condition. SHM is the recognized method for increasing safety and operational efficiency.

Our team of experts designed a comprehensive Structural Health Monitoring System specifically for conveyor belt operators, to analyze the forces and temperature factors that contribute to damage, including: design, construction and deterioration of materials. MS Systems incorporates several sensor technologies, including: multipoint humidity sensors, Temperature sensor chains, and distributed fiber optic sensors, to provide precise, real-time information about infrastructure changes. With so many factors impacting the construction and ongoing operation of conveyor belt systems, our customers appreciate the peace of mind they gain through deploying a monitoring system from MS.

Get in touch with one of our expert team members to discuss your goals today.

Structure

Sensors

Data acquisition systems

Data transfer and storage mechanism

Data management

Data interpretation and diagnosis

MS Scorpion provides a comprehensive system to monitor and assess the real-world factors affecting conveyor belt operation. With MS Scorpion’s SHM your company will have the information you need to diagnose and repair problems as they arise.

MS Scorpion’s Distributed Structural Health Monitoring (DSHM) approach provides our customers with a complete solution, utilizing ultra-sensitive sensors, such as: multipoint humidity sensors, Temperature sensor chains, and distributed fiber optic sensors.

Monitor infrastructure degradation and receive warning notifications to perform preventative maintenance.

Actively monitor critical components to assess current condition, and establish a maintenance plan for performing repairs to increase longevity.

Establish a system to actively monitor the implementation of new construction technologies and determine their effectiveness.

Get an immediate status update about the conveyor belt’s health, including possible damage and failures.

The MS Scorpion Structural Health Monitoring system can be deployed to effectively address both continuous monitoring and portable testing needs.

Customers seeking a dynamic system to perform diagnostics on the current health of a structure will achieve their goals with the MS Scorpion system.

For customers looking to collect data and provide ongoing information on the behavior and health of their structure, the MS Scorpion SHM platform is ideally suited for long-term monitoring needs.

Let MS Systems become your trusted partner for your conveyor belt’s SHM. We provide innovative solutions that serve our customers needs through ultra-reliable performance and long product life. We believe in providing clear information about each service we offer, and the standards we aim to achieve. Our experts will guide all phases of the project, from system design, installation, commissioning and training.

Our team of experts will work closely with you during design, technology selection, and system optimization.

MS Systems provides service and support during and after installation, with a wide range of additional services and extended global warranties for every system we supply.

MS Systems provides ongoing technical support from installation, commissioning and beyond.

MS Systems provides a unique approach to structural health monitoring, delivering real-time data and analysis for our customers to reduce downtime by monitoring assets and notifying key members before it reaches a critical state.