Explore Monitoring System’s (MS) unique approach to Fire Detection Monitoring, helping businesses detect and alert key personnel to fires within subways, tunnels, and other enclosed structures. Click to learn more about our state-of-the-art services, or get in contact with one of our knowledgeable representatives to discuss adding this instrumental safety service today.

Learn More Get in TouchThe MS Fire Detection Monitoring System provides our customers with the tools they need to ensure safety of passengers, staff, and equipment.

Our real-time monitoring services deliver continuous infrastructure analysis, offering complete information about the system’s health.

Should a fire occur, predefined thresholds within the system instantly triggers a notification to any members you designate to take appropriate action.

With our system in place you will have all information you need to make an informed and timely decision, thereby improving response time and mitigating damage.

With so many factors at play within subway and tunnel systems, an active feedback monitoring system, offers our customers peace of mind where traditional fire detection systems fail.

With the MS Fire Detection Monitoring System, operators can improve management and safety by regularly analyzing system health parameters.

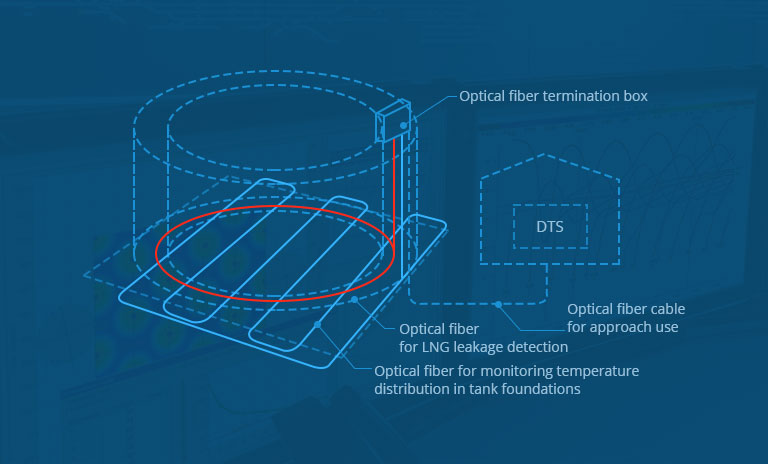

Advanced sensors and software are at the core of the MS Fire Detection Monitoring System’s technology. Distributed Temperature Sensors (DTS), in conjunction with an integrated software system, measure temperature differences over time and alert system operators when abnormalities occur.

Our customers agree, with the MS Fire Detection Monitoring System in place, you’ll have all the information you need to make an informed decision.

Get instant feedback about your critical infrastructure from the MS Fire Detection Monitoring System.

Innovative technology powered by fiber-optic DTS and an integrated software system.

Actively monitor your infrastructure to detect damage before it reaches a critical state.

Timely alerts can provide system operators more time to alert passengers and staff to follow evacuation procedures.

Advanced sensors and software are at the core of our technology. Distributed Temperature Sensors (DTS), in conjunction with an integrated software system, measure temperature differences over time and alert system operators when abnormalities occur.

Implementing fiber optics sensing technology provides an ultra-stable, continuous sensor over long distances to detect temperature distribution changes.

These systems are highly accurate, providing real-time location information following an event.

Through recent developments in technology, our services can provide fiber-optic system monitoring along 60 km of electrical lines using a single fiber, and extended applications of up to 300 km with the use of optical amplifiers.

With the ability to measure temperature and strain over thousands of points along a single fiber, our customers can apply this essential technology to perform other monitoring needs such as: verifying structural integrity, detecting deformation, and preventing failure in landslide prone areas.

Leaking buried pipelines pose a very serious problem to pipeline owners for many reasons. Financially, due to the waste of valuable product, environmentally because the product may leak into surrounding soil and contaminate the ground, and safetywise, particularly if the leak is inside industrial facilities, when the product is flammable. Shutting down a pipeline that is suspected to leak may also lead to serious operational and financial implications (shortages, inability to deliver, contractual issues etc.). Occasionally, there are indications of a leak, e.g. when pressure is dropping for no other obvious reason or when product is visible in nearby valve wells, pipe ground exit points, seawater, on the ground itself etc. Even then, it is generally difficult to reliably locate the exact position of the leak so as to take corrective measures. In the worst case, a leak may go on unnoticed, such as in some cases of complex networks, or when it is not large enough to become visible.

Access to the pipeline is required only every about 100-200m for mounting AE sensors. Pipeline is pressurized in 500-1000m sections at a time, while the AE sensors detect the turbulent flow at the leak orifice, and, with the use of digital AE systems and specialized data acquisition and analysis software, provide the position of the leak. The method has been proven effective, fast and accurate in detecting and locating leaks, and it is now being used also as a preventive leak control tool for long underground transfer pipes or short, buried pipe sections, such as dikes and road crossings. Acoustic emission sensors operating between 20 and 100 kHz are mounted on the pipeline, monitoring both continuous and burst type emissions through simultaneous acquisition of Time Driven Data (threshold independent sampling) and Hit Driven Data (threshold dependant). In addition to that, acquisition of AE waveforms or waveform streaming is often used as a further evaluation tool.

Leaking valves are a common problem with results showing that 5 to 10 percent of the valves in Oil and Gas plants leak. More importantly, it was determined that just 1 to 2 percent of the valves accounted for approximately 70 percent of the losses. Valve leak detection works by detecting the “noise” produced as the medium passes through the valve as “turbulent” flow. Turbulent flow creates a signal with frequency components well over 100 KHz. This allows the use of high frequency acoustic emission sensors with frequencies above the vibration and background noise level of the plant. This characteristic makes reliable detection and quantification of leaks possible. In addition to being able to determine if a valve is leaking, our proprietary algorithms allow us to “quantify” the amount of the leak.

Successful detectability of leaks with AE depends upon the distance of the leak from the AE sensors, the attenuation characteristics of the pipe material (thickness, material etc.) and the type of fluid (gas, liquid) inside the pipe. It also depends upon the surrounding environment (air, soil) and the condition (Reynolds number) at the leak orifice, which, in turn, depends on flow rate, differential pressure, orifice size, and type of fluid.

Pipeline Integrity Monitoring System (PIMS) provides real-time integrity monitoring and is based on Brillouin or Raman scattering, FBG and/or Acoustic Emission (AE) sensing depending on the project requirements. MS Python Monitoring System detects and locates small temperature and or strain changes along the entire length of a pipeline continuously, in real time.

At MS Systems we provide innovative solutions that serve our customers needs through ultra-reliable performance and long product life. We believe in providing clear information about each service we offer, and the standards we aim to achieve.

Our team of experts will work closely with you during design, technology selection, and system optimization.

MS Systems provides service and support during and after installation, with a wide range of additional services and extended global warranties for every system we supply.

MS Systems provides ongoing technical support from installation, commissioning and beyond.

MS Systems provides a unique approach to fire detection monitoring, delivering real-time data and analysis for our customers to reduce downtime by monitoring assets and notifying key members before it reaches a critical state.