MS Python’s innovative remote monitoring system is designed to help onshore and offshore platforms monitor the operational health of their downhole equipment. With our experience in the market we can supply both standard systems, from our pool of field-proven equipment, or develop customized solutions with state-of-the-art sensors and instrumentation, to suit individual project requirements.

Learn More Get in TouchOur extensive experience in the oil and gas industry allows us to provide our customers with practical recommendations and solutions based on their project needs.

This expertise extends to the installation of monitoring systems in both normal and hazardous environments.

We provide fast and efficient monitoring services, offering accurate solutions to problems, including collating, analyzing, interpreting, and reporting all recorded data. We can further tailor data to your requirements, including quality control and presentation, fatigue calculations, or spectral and modal analysis of structural responses.

Our MS Python Monitoring System provides a cost-effective method for assessing the integrity of downhole structures for design verification. With our advanced tools, we can help increase downhole depths by up to 30%, while providing critical information, such as temperature changes, along all length of downhole bore.

By implementing MS Python monitoring services, environmental and structural parameters can be measured to verify structural performance during jack up and jack down operations thereby reducing operational downtime.

MS Python offers a range of structural measurement services to support safe and efficient downhole construction operations.

Construction support services include:

MS Python Monitoring System for downhole infrastructure provides customers with advanced tools and information to build and maintain smarter structures. With MS Python in place, you will have all the information you need to identify the precise location of the problem and make an informed decision to repair it.

MS Python’s monitoring services deliver complete solutions seamlessly combining Fiber Bragg Grating (FBG) technology, distributed fiber-optic sensors, and High Degree of Freedom (DOF) sensors into an integrated system. Through this approach, the system can be easily scaled to any size and configuration, with all data synced through a central monitoring center.

Monitor performance degradation and receive warning notifications to perform preventative maintenance and ensure the safety of personnel following significant events.

Increase system lifecycles by actively monitoring the operational health of downhole structures. Implement a system that can remotely monitor parameters such as temperature change, sand deposit, and environmental changes. Develop better maintenance schedules and reduce operational costs.

Put a monitoring system in place to keep track of damage to your downhole structures during construction and throughout its lifespan. With monitoring in place, remedial actions can be efficiently prioritized, and long-term effects can be monitored to minimize catastrophic failure.

By investing in a system to monitor your existing structures, you will gain critical information on designing similar objects for future projects.

Get an immediate status update about the system’s health, including possible damage and failures, following adverse events.

At MS Systems we provide innovative solutions that serve our customers needs through ultra-reliable performance and long product life. We believe in providing clear information about each service we offer, and the standards we aim to achieve.

Our team of experts will work closely with you during design, technology selection, and system optimization.

MS Systems provides service and support during and after installation, with a wide range of additional services and extended global warranties for every system we supply.

MS Systems provides ongoing technical support from installation, commissioning and beyond.

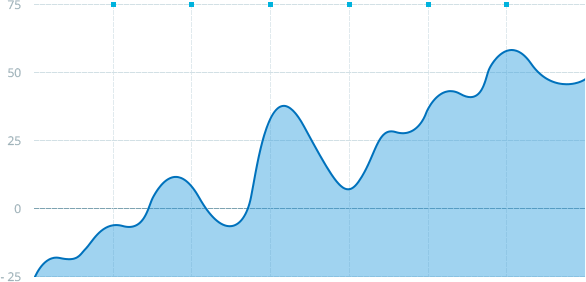

MS Systems provides a unique approach to structural health monitoring, delivering real-time data and analysis for our customers to reduce downtime by monitoring assets and notifying key members before it reaches a critical state.